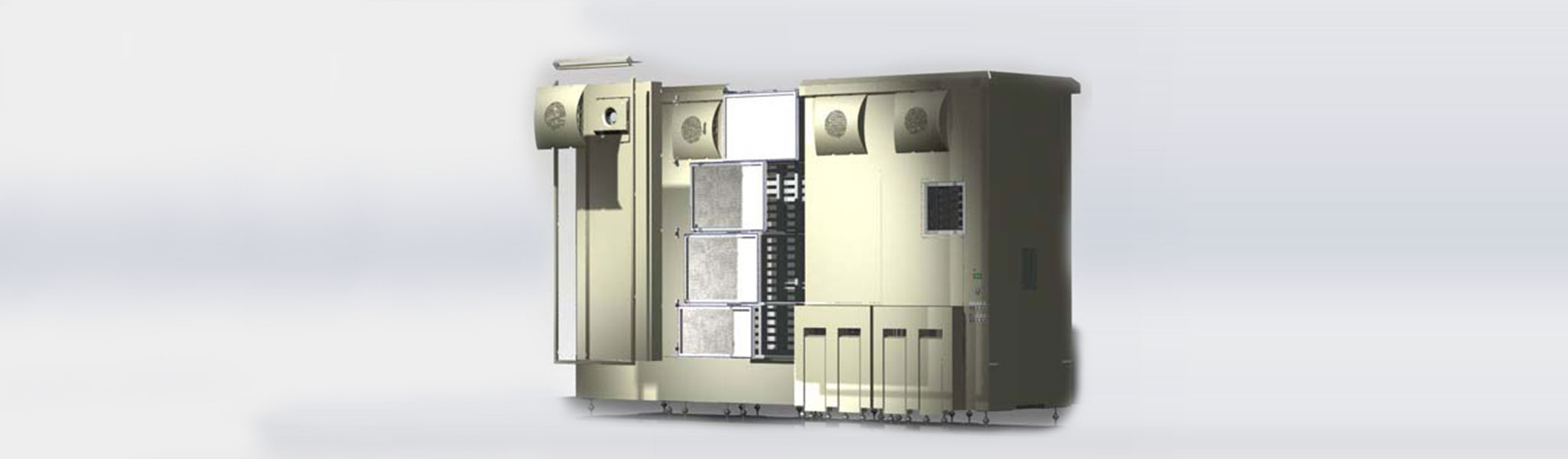

Intelligent Enclosures

Mini Environments

Hard & Softwall

Modular Cleanrooms

Laser Infrometer

Enclosure

Learn more about us

View our products

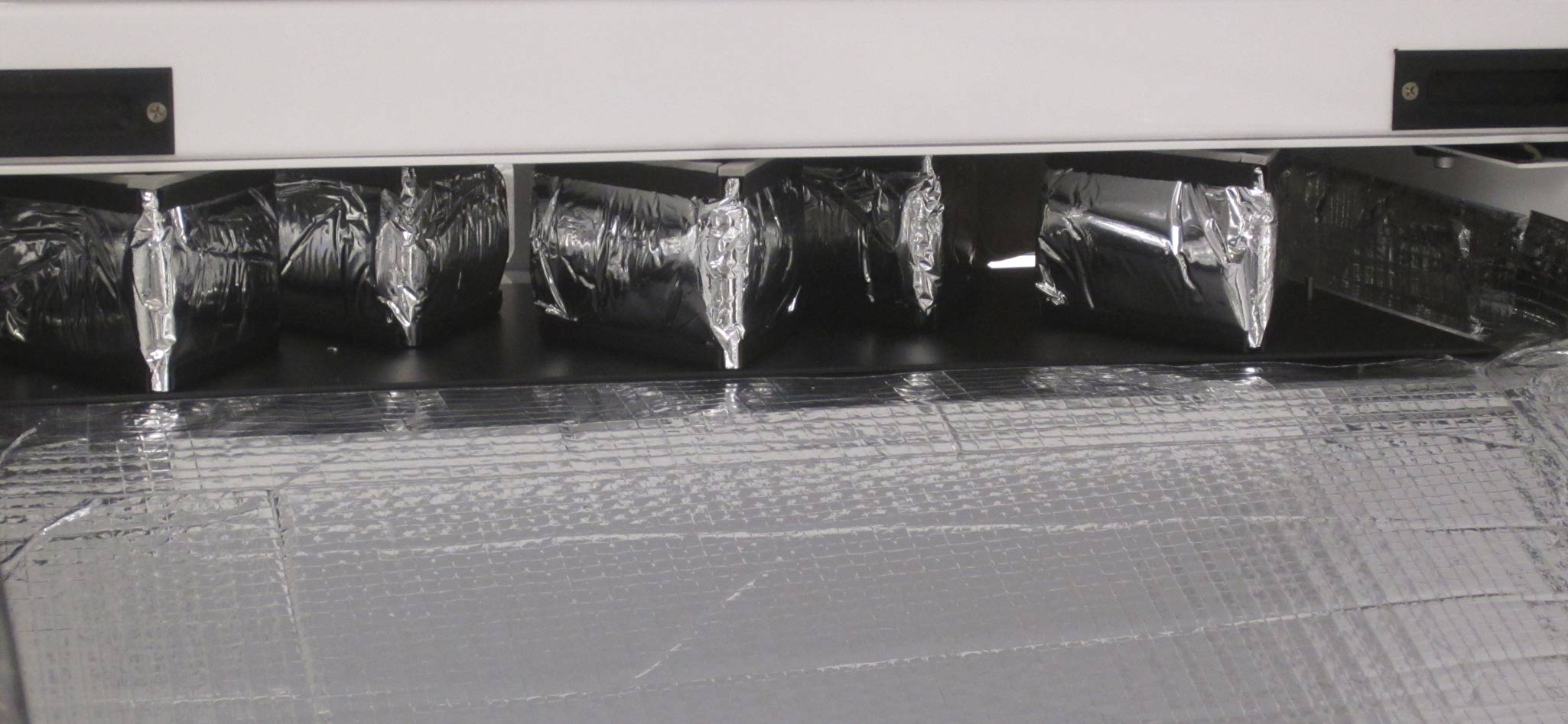

Air System With

Environmental Control

Learn more about us

View our services

Air System With

Environmental Control

Learn more about us

View our services

-

01

Environmentally,

Controlled EnclosuresiE offers control over critical environmental conditions to achieve high performance standards:

-

02

Hard & Softwall

Modular CleanroomsMicroelectronics and USP <797> & <800> Compliant

-

03

Temperature Control

EnclosuresTemperature ± 5 mK (± 0.005 ºC) Stability, ± 10 mK (± 0.010 ºC) Spatial Uniformity

-

04

Particulate Control

EnclosuresHumidity ± 0.50% RH Stability

-

05

Acoustic Control

EnclosuresAcoustic 10 dB attenuation >50 Hz from ambient, with greater reductions possible

-

06

Testing &

CertificationCleanrooms and biosafety Primary Engineering Controls

-

-

Leaders in Environmental Control

and MiniEnvironment Enclosure TechnologyCritical Acoustic, Humidity, Temperature, Particulate & Pressurization Control

As both semiconductor and nanotechnology manufacturing processes, and metrology applications, demand more challenging levels of environmental control, Intelligent Enclosures [iE] has developed leading edge environmental control solutions, and gained practical experience in manufacturing MiniEnvironments which achieve levels of control not attained previously.

Additionally iE MiniEnvironments offer ESD Control, AMC Filtration, EMI & RFI Abatement, Vibration Reduction, and Illumination.

Learn more

Critical Environmental Enclosures Services - Including Manufacture, Integration & Installation

-

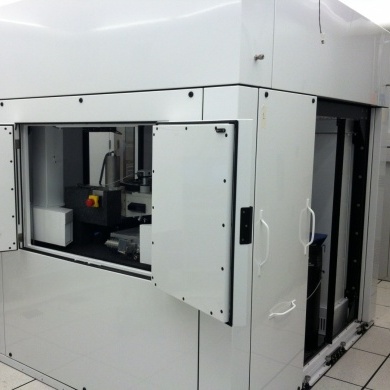

Sophisticated Environmental Enclosures

We Build Mini Environments to your Specifications

iE works collaboratively with major semiconductor manufacturers, tool builders, research organizations, universities, and technology start-ups to conceive, design and manufacture cutting edge MiniEnvironments that enable our Customers to achieve their goals. These include developing sub-32nm node processes, creating laser gratings with nanometer precision spacings, or developing microscopes for analysing substances at the sub-atomic level.

Learn more -

-

-

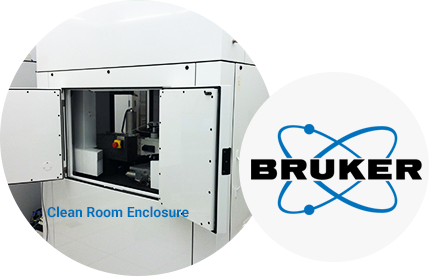

USP Compliant CleanRooms <USP-797> <USP-800>

Isolation and environmental control has taken a huge step forward for the medical device and pharmaceutical industries, thanks to this innovation.

Learn More

-

-

Testing & Certification

Intelligent Enclosures is a leader in the controlled environment field. We specialize in the supply of USP-800 and USP-797 approved cleanrooms and are also RCCP-SCF Certified.

Learn More

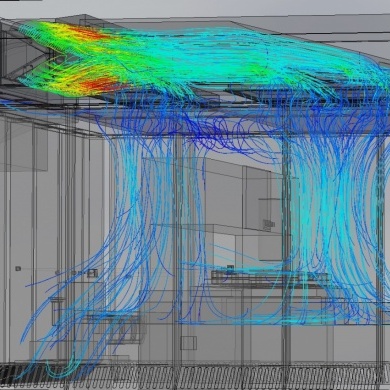

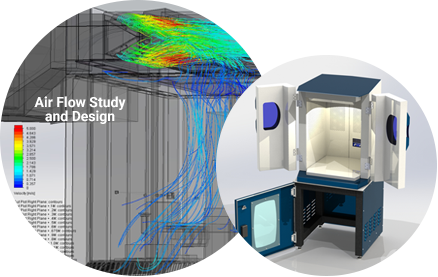

Proven Methodology from Design, Engineering to Production

Engineering & Design Solutions for Any Enclosure.

iE develops engineering and design solutions using computational fluid

dynamics [CFD] and 3D parametric modeling software, which allows us to

work collaboratively with our Customer to create an environmental

solution for their needs. Combined with our decades of experience in

creating MiniEnvironments, our software portfolio allows us to develop

unique solutions to problems specific to each Customer.

One-offs or Mass Production

We have experience, team and capabilities to product your enclosure.

Following agreement with our Customer on the engineering and design approach, iE then progress to proof of concept, first article production, and to manufacturing production volumes. All assembly, testing, and integration activities are undertaken in our Clean Room providing control of all aspects of the project. We also undertake worldwide installation and commissioning activities to support our Customers.

Learn more-

-

quote-right

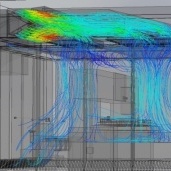

UCLA was in need of a nanotech research enclosure. IE consulted in all stages of the design process including air flow studies, design, engineering, manufacturing and installation.

Read the full case study

-

-

quote-right

Daifuku contacted IE to build an air flow system...

Read the full case study